Overview

Work

Sustainable Energy

- UCOST Home

- Sustainable Energy

- You are Here

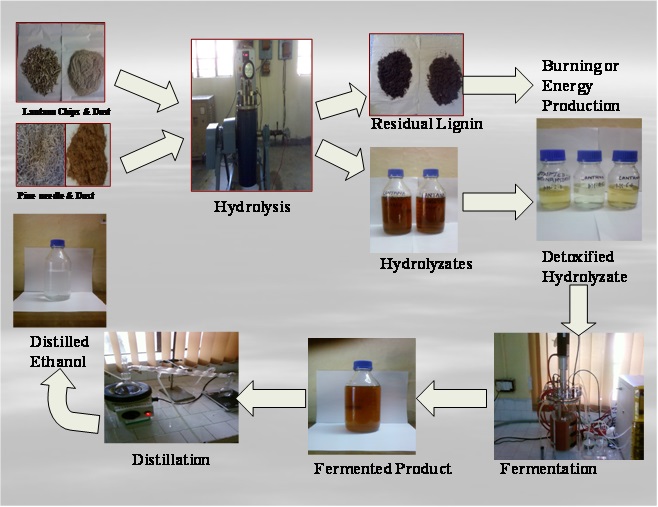

Bioconversion Of Forest Waste Lignocellulosic Biomass Into Ethanol

Production of second-generation liquid transportation fuel (bioethanol) utilizes more abundant biomass such as forestry based lignocellulosic residues. It is promising over first-generation bioethanol which utilizes starch, corn, wheat and sugarcane molasses for its production. Technologies to convert lignocellulosic biomass into bioethanol are available, however, they have not yet been commercialized primarily because a number of processing steps required to break complex network of hemicelluloses, cellulose and lignin to make it accessible to hydrolysis resulting release of simple sugars and fermentation. In view of Uttarakhand's abundant forest resources, their utilization for bioethanol production holds promising prospects. PI has successfully demonstrated the process technology for hydrolysis of hemicellulose and cellulose content of Lantana camara and Pine needle, detoxification of hydrolyzate, fermentation of hydrolyzed glucose and xylose sugar into ethanol using Pichia stipitis NCIM- 3499 and Saccharomyces cerevisiae NCIM- 3570 and finally distillation and recovery of alcohol. Different set of reactions were carried out in two series under various reaction temperature, reaction time and acid concentration to optimize the hydrolysis process in order to extract maximum fermentable sugars. The maximum sugars extracted in scaled up experiments of first series experiments were 40.2 g/l (66.65%) with 1.20% average phenolics in case of Lantana camara while it was 33.9g/l (56.20%) with 1.55% average phenolics in case of Pine needle. The hydrolyzates with maximum TRS content was detoxified with Ca(OH)2 followed by activated charcoal. The detoxified hydrolyzate of first series experiments was subjected to fermentation with Saccharomyces cerevisiae NCIM-3570 and produced 9.35g/l (11.76%) ethanol with 70.56% fermentation efficiency in Lantana camara while it was 7.06g/l (8.88%) ethanol with 64.59% fermentation efficiency in case of Pine needles. Second series of experiments extracted maximum sugars 35.40 g/l (29.47%) with 0.73% phenolics in case of Lantana camara while it was 32.37 g/l (26.95%) with 0.46% phenolics in case of Pine needle at 1200C for 90 minutes reaction time. The pre-extraction of Lantana camara with methanol and pine needle with alcohol-benzene reduced the load of phenolic content by 18.9% and 65.92% respectively. An interesting result was obtained first under the current study when hydrolyzates of second series experiments were further heated under optimized conditions. There was an increase in total reducing sugar (TRS) content which could be due to the breakdown of oligomeric sugars present in the lignocellulosic hydrolyzates. The hydrolyzates containing maximum sugar content was detoxified by 20% Ca(OH)2 slurry followed by activated charcoal. The detoxified hydrolyzates of Lantana camara and Pine needle obtained from second series experiments was fermented by Saccharomyces cerevisiae NCIM-3570 in two different medium. Among these two mediums the hydrolyzate was fermented with maximum 80.72 % fermentation efficiency and produced 10.31 g/l (8.58%) ethanol in case of Lantana camara while the Pine hydrolyzate was fermented with 79.75% fermentation efficiency and produced 9.16g/l (7.63%) ethanol in the medium against the conventional one.

|

Social Media Links